WS2 - Tungsten Disulphide Powder Lubricant - 0.6 micron APS Micronised - ultra performance

WS2 - Tungsten Disulphide Powder Lubricant - 0.6 micron APS Micronised - ultra performance

Couldn't load pickup availability

Micronised WS2 (Tungsten Disulphide) powder - highly refined powdered lubricant for many advanced applications

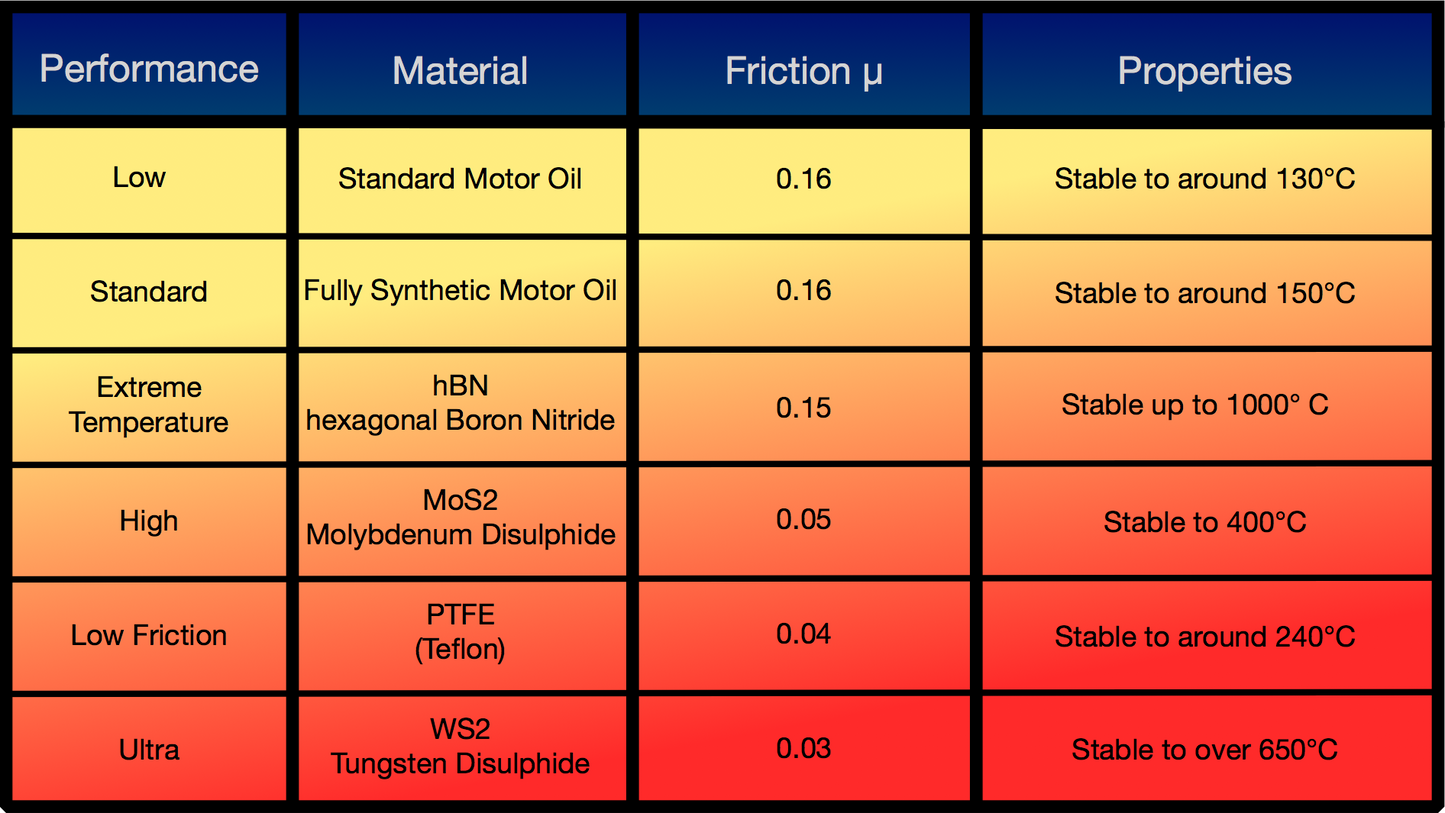

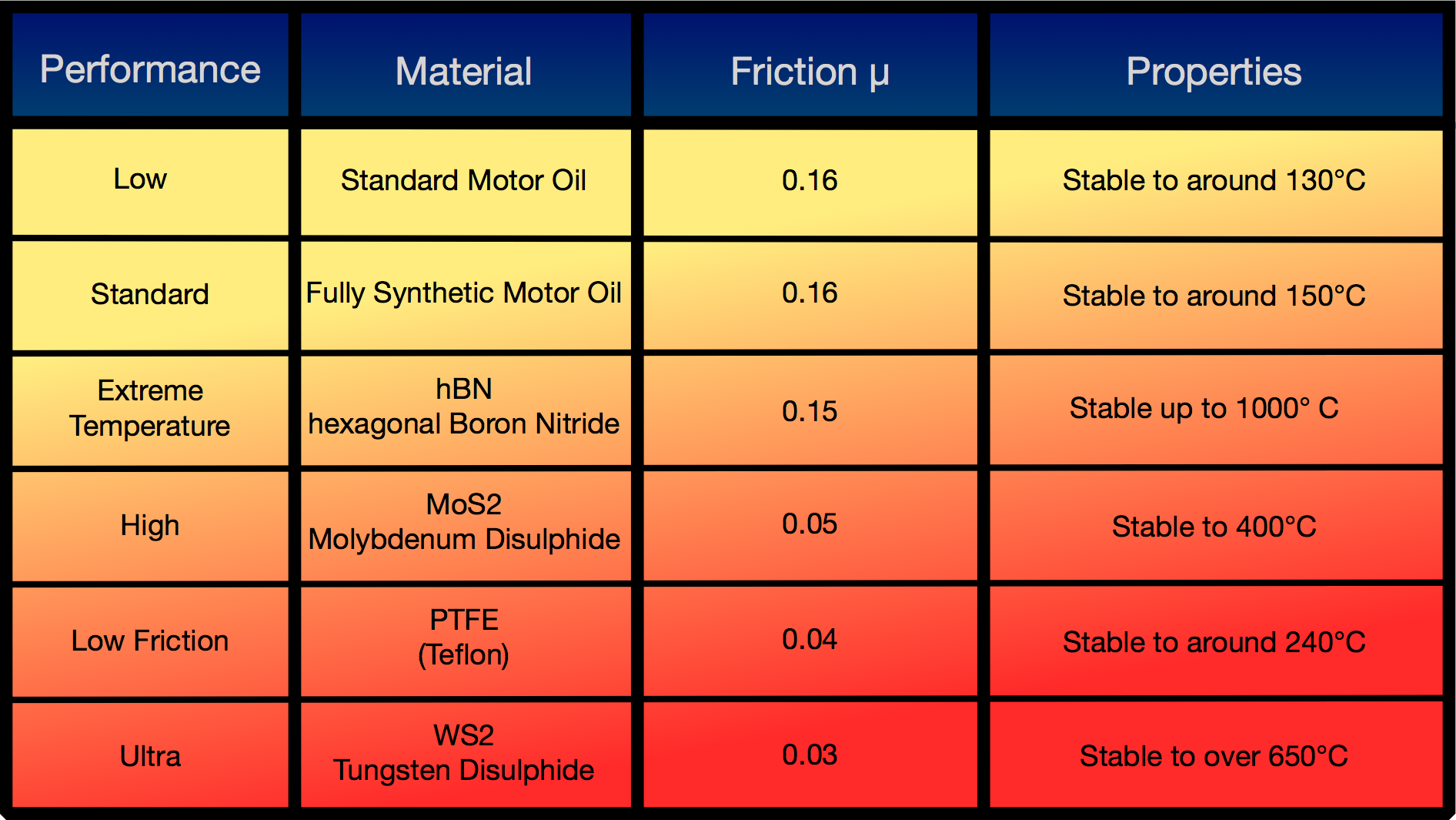

- Incredibly low co-efficient of friction 0.03 - better than MOLY, PTFE or even wet ice on wet ice! Increases power transmission and reduces wear

- Can be mixed with other greases to act as a fortifying, friction reducing additive

- Ultra low friction - works over a wide temperature range -270C to +650C - practically inert - even works in space!

- Varied uses: Engine and gearbox builds (motor racing, advanced engineering), Oil and grease additive, dry lubricant etc

- Not widely commercially used - give yourself an edge in performance

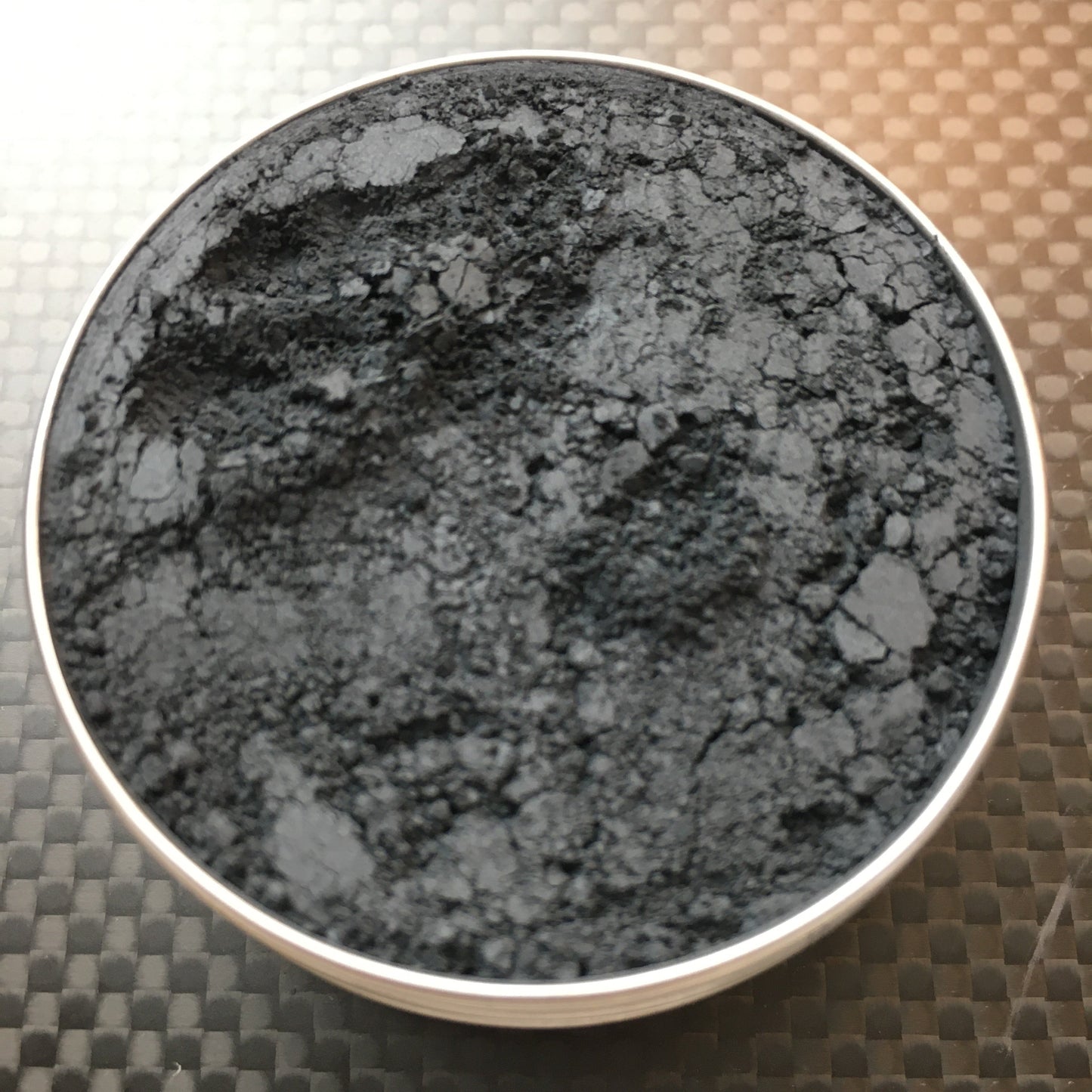

15g tins or 25g, 50g or 100g resealable foil pouches of 0.6 micron APS Ultra Grade Micronised Tungsten Disulphide (WS2) Powder. For a wide range of engineering, automotive and other lubrication applications. Ideal for racing engine rebuilds where low friction is paramount. Apply to bearings, sliding surfaces and other moving parts on engines, robot gearboxes, 3D printers and automotive. Can be used to reduce noise and increase life span of gears etc.

Use directly or as an additive with greases or oils. Can be mixed with isopropyl alcohol and painted on to surfaces to leave a thin layer of ultra performance lubricant. May be 'burnished' on to metals to give a fine low friction coating just microns thick.

Tungsten Disulphide is a dense grey - black powder. It adheres to many surfaces leaving a metallic slippery layer about half a micron thick. WS2 is made up of many thin sheets that are held together by very weak van de waals forces. It is the weakness of these forces that allow WS2's layers to slip so easily over one another.

WS2 is not widely used giving exclusivity and unrivalled performance. Substantially cheaper MoS2 is commonly used by major lubricant manufacturers but WS2 had remained far rarer. In the few commercial products we have seen using WS2 they are using very low percentages often bulked out with MoS2, which is fine, but not as good. WS2 is used by those that are looking for the cutting edge of useable lubrication technology.

Share